How Does The Battery Regeneration Machine Work?

Battery Regeneration Machine renews old lead acid batteries by enabling a complex chemical reaction process. Without regular maintenance, industrial machines fail to function efficiently. In this blog, we'll understand battery regeneration and its process.

Battery Regeneration Machine: What Is It And How Does It Work?

A battery regeneration machine helps in renewing old lead acid batteries for extended, efficient, and economical use. Areas benefiting from battery regeneration include:

- Hospitals

- Solar Power

- Military Tools

- Battery Shops

- Electric Forklift

- Agricultural Apparatus

- Telecom & Broadcasting

Batteries exhaust their potential due to reasons like improper use and sulphation. Sulphation lowers battery capacity by forming micro lead crystals of sulfates, preventing proper recharging.

If your battery heats up quickly or takes time to recharge, it's time to regenerate it. But what is battery regeneration technology? Let's find out.

What Is Battery Regeneration?

Battery regeneration involves disintegrating wasteful clusters on lead acid batteries by applying voltage-monitored electronic pulses. This action renovates the battery's layers.

Why Battery Regeneration Is Important?

After regeneration, you can use your old battery for an extra 4-5 years as it extends its life by 3x. Lead acid battery regeneration extends battery shelf life and reduces future costs.

The Process Of Battery Regeneration

The battery regeneration process involves an electrochemical operation to revive the old and used battery. Generally, a lead acid battery uses lead and sulfuric acid to perform well. When the lead acid battery is in a non-crystalline solid state (amorphous state), lead sulfate forms crystals over the battery that prevent it from changing into sulfuric acid.

Due to continuous discharge over time, sulfur breaks away from the existing sulfuric acid and forms crystals over the lead plates. These sulfur layers disintegrate when regenerators apply a high-voltage electronic pulse and reinstate the status quo of the sulfuric acid.

At Sun C, we follow a 7-step process to ensure the quality regeneration of lead-acid batteries.

Step 1Initial Assessment: We examine your battery’s condition with diagnostic tools and test it as per the parameters of voltage, capacity, internal resistance, and overall physical condition.

Step 2

Desulfation: The Sun C regenerator machine breaks down the sulphate crystals on the battery plates, employing the desulfation technique of pulse charging. Here, short bursts of high-current pulses are sent across the battery to dissolve the sulphate crystals without harming the battery plates.

Step 3

Recharging: Following desulfation, the Sun C regenerator machine controls the charging process of the battery to ensure an efficient recharge. However, it may use conventional or specialized charging methods depending on the battery’s requirement.

Step 4

Monitoring and Control: Throughout, the Sun C regenerator machine monitors the different parameters like voltage, temperature, and charging/discharging rates. The machine’s intelligent control system adjusts the entire process based on real-time data and feedback from the battery to safely optimize the effectiveness. The regenerator machine includes protective features against overcharging, overheating, or other potential hazards.

Step 5

Capacity Testing: The next step is to test the battery’s capacity after its recharge to assess the regeneration process’s effectiveness. This step discharges the regulated battery and measures its energy delivery.

Step 6

Completion and Reconnection: Once the regeneration process is over and the battery’s performance is restored, the Sun C team reconnects it to the intended application. We still monitor the post-regeneration performance of the battery to ensure the battery’s functionability.

Step 7

Follow-Up Maintenance: To extend the success of the regeneration process, we give regular maintenance like periodic cycles of charging/discharging and implement preventive measures against further sulphate buildup.

The regenerators gauge the frequencies of the electronic pulses and also control the overall temperature. So, it is crucial to use quality regenerators as the only option for this process.

The Benefits Of Battery Regeneration

Every year, battery prices rise by 12-15%. Regenerated batteries can give your machine a solid backup and renew 90-95% of your old battery’s initial electrical capacity. The regenerated batteries also restrict your power consumption by taking less time to recharge, consequently saving electricity.

So, instead of throwing away your old batteries due to their poor performance, regenerate them to renew and maximize their use potential. Thus, by saving your battery, you save money, time, and the environment, too. In a gist, battery regeneration -

- Recovers your battery to its initial capacity by 90%.

- Protects the environment by recycling the used batteries.

- Limits your battery’s power consumption during recharge.

- Saves up your money by 70% by not letting you spend on new batteries.

With their latest models in battery regeneration machines, Sun C pioneers in this space. If you want to start a battery regeneration business in India, Sun C equips you with all the machines and modern-day training to set it up.

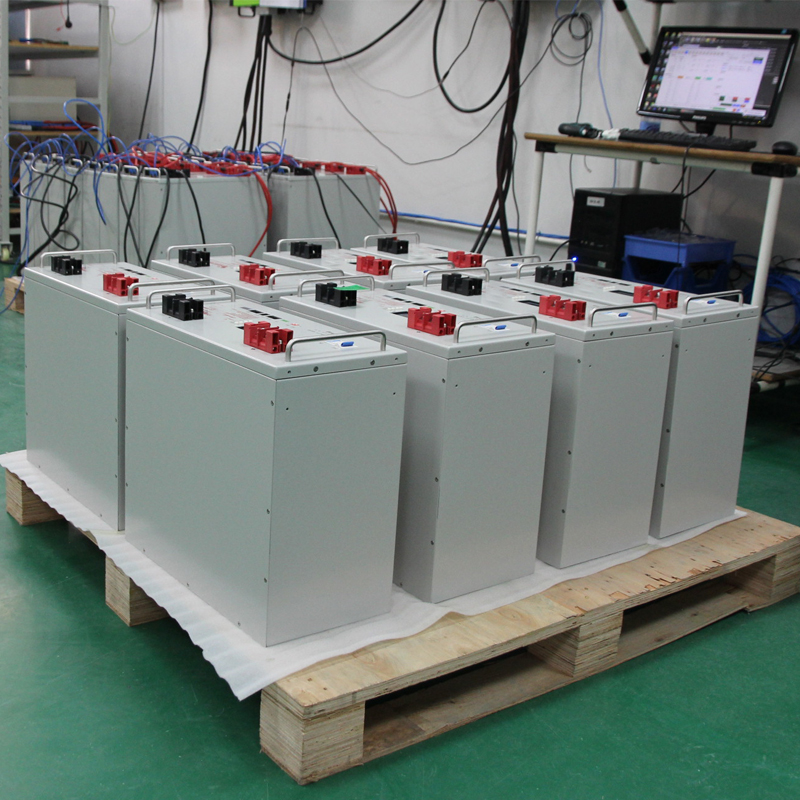

Battery Regeneration Machine

As we conclude here, we hope you have an idea of battery regeneration and its processes and benefits. There are many battery regeneration companies in India. But, always take an expert’s intervention to use this technology. Sun C is one of the top battery regeneration machine manufacturers in India, thanks to our premium services, multiple centers across the country, and a huge body of clientele trusting us.

Sun C Battery Regeneration Machine Price

How much will a battery regeneration machine cost? If you want to know the battery regeneration machine price in India, Sun C can help you. We have successfully regenerated 15000+ batteries and have 75+ regeneration centers across India providing sustainable and cost-effective regeneration solutions.